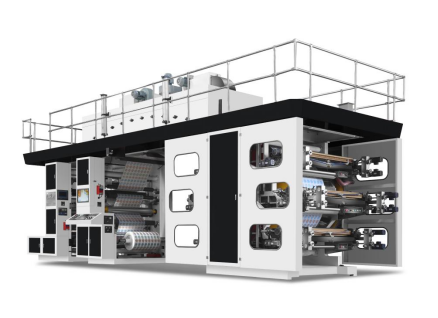

Ana iya amfani da Drum na Tsakiyar Maƙallin Bugawa na Cl Flexo a matsayin wani ɓangare na na'urar daidaita matsin lamba. Baya ga aikin babban jikin, matsayinsa a kwance yana da tsayayye kuma yana da karko. Na'urar canzawa akan rukunin launi na bugawa tana kusa ko ware daga na'urar birgima ta tsakiya. Samu ikon sarrafa matsin lamba akan kayan bugawa. Ana tuƙa drum na tsakiya kai tsaye ta hanyar injin juyawa na Siemens. Abu mafi bayyane shine cewa an cire motar servo ta gargajiya tare da akwatin ragewa. Fa'idar ƙira ta wannan tuƙi kai tsaye ita ce: dangane da ƙaramin lokacin inertia, babban watsa karfin juyi, tsarin sanyaya ruwa zai iya Inganta ƙarfin da aka ƙima, babban ƙarfin ɗaukar nauyi, babban amsawar motsi da ingantaccen bugu.

● Bayanan Fasaha

| Samfuri | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Matsakaicin faɗin Yanar Gizo | 700mm | 900mm | 1100mm | 1300mm |

| Matsakaicin Faɗin Bugawa | 600mm | 800mm | 1000mm | 1200mm |

| Matsakaicin Gudun Inji | 350m/min | |||

| Matsakaicin Saurin Bugawa | 300m/min | |||

| Mafi girman sassauci/Ja da baya Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Nau'in Tuki | Drum na tsakiya tare da Gear drive | |||

| Farantin Fotopolymer | Za a ƙayyade | |||

| Tawadar | Tawada mai tushe ta ruwa | |||

| Tsawon Bugawa (maimaita) | 350mm-900mm | |||

| Kewayen Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nailan, | |||

| Samar da Wutar Lantarki | Wutar lantarki 380V.50 HZ.3PH ko kuma wanda za a ƙayyade | |||

● Gabatarwar Bidiyo

● Na'urar kwancewa

Sashen sassauta injin Ci flexo yana ɗaukar tsarin tsarin tashar biyu mai zaman kansa na turret mai juyawa biyu-axis, wanda zai iya canza kayan ba tare da dakatar da injin ba. Yana da sauƙin aiki, yana adana lokaci da kayan aiki; Bugu da ƙari, ƙirar sarrafa atomatik na PLC na iya rage tsangwama ga ɗan adam yadda ya kamata da kuma inganta daidaiton yankewa; Tsarin ganowa ta atomatik na diamita na birgima yana guje wa rashin amfanin shigar da hannu lokacin canza birgima. Ana amfani da na'urar gano diamita na birgima don gano diamita na sabon birgima ta atomatik. Tsarin tsarin gano tashin hankali yana sarrafa juyawar gaba da baya na injin, wanda zai iya sarrafa tashin hankali na tsarin yadda ya kamata.

● Na'urar bugawa

Tsarin naɗin jagora mai ma'ana yana bawa kayan fim ɗin damar yin aiki yadda ya kamata; ƙirar canza farantin hannun riga tana inganta saurin canjin farantin sosai kuma tana tabbatar da ingantaccen bugu mai yawa; na'urar scraper da aka rufe tana rage fitar da ruwa mai narkewa kuma tana daidaita danko, wanda ba wai kawai yana guje wa fesawar tawada ba, har ma yana iya tabbatar da danshi mai dorewa na bugawa; na'urar anilox ta yumbu tana da babban aikin canja wuri, tawada tana da daidaito kuma santsi, kuma tana da ƙarfi da dorewa; hanyar haɗin injin ɗan adam yana hulɗa da PLC don sarrafa ɗagawa ta atomatik bayan saita bayanai.

● Na'urar sake kunnawa

Tuki mai hawa biyu mai hawa biyu, canjin abu ba tare da tsayawa ba, aiki mai sauƙi, adana lokaci da kayan aiki; PLC da maɓallin lantarki suna sarrafawa ta atomatik kuma suna gano ainihin matsayin yankewa, rage kurakurai da matsaloli da aikin hannu ke haifarwa, da kuma inganta nasarar ingancin yankewa; ƙirar abin birgima mai buffer yana guje wa tasiri mai yawa yayin canja wurin tef kuma yana rage canjin tashin hankali; tsarin canza birgima yana ƙarƙashin tsarin PLC don tabbatar da cewa an daidaita shi da saurin mai masaukin baki; firam ɗin juyawa mai zaman kansa yana da daidaiton sarrafawa mai yawa kuma yana da sauƙin aiki; naɗaɗɗen Taper ɗin yana ɗaukar kulawar atomatik ta amsawa ta atomatik don tabbatar da daidaiton tashin hankali a ciki da wajen birgima da hana wrinkles a cikin kayan fim ɗin da aka birgima.

●Tsarin Busarwa na Tsakiya

Tsarin busarwa yana da tsari mai inganci da ƙarancin narkewar abubuwa, kuma samfurin yana da ƙarancin ragowar sinadarai; tanda tana ɗaukar ƙirar matsi mara kyau don hana iska mai zafi fitowa, kuma ana sarrafa zafin ta atomatik tare da babban daidaito; ƙarancin zafin jiki da babban ƙarfin iska na iya samar da shebur iska, wanda ke adana kuzari sosai.

Lokacin Saƙo: Mayu-20-2024